The pharmaceutical industry has the highest requirements for hygiene, sterility, and precision. Stainless steel equipment used in pharmaceutical production must comply with strict standards to prevent contamination, ensure product safety, and maintain regulatory compliance.

Whether it's pharmaceutical production, research laboratories, or sterile treatment environments, the performance and cleanliness of your stainless steel equipment directly impact the quality of your products. To maintain these standards, regular servicing, maintenance, grinding, polishing, and welding are crucial to ensure long-lasting sterility, durability, and compliance.

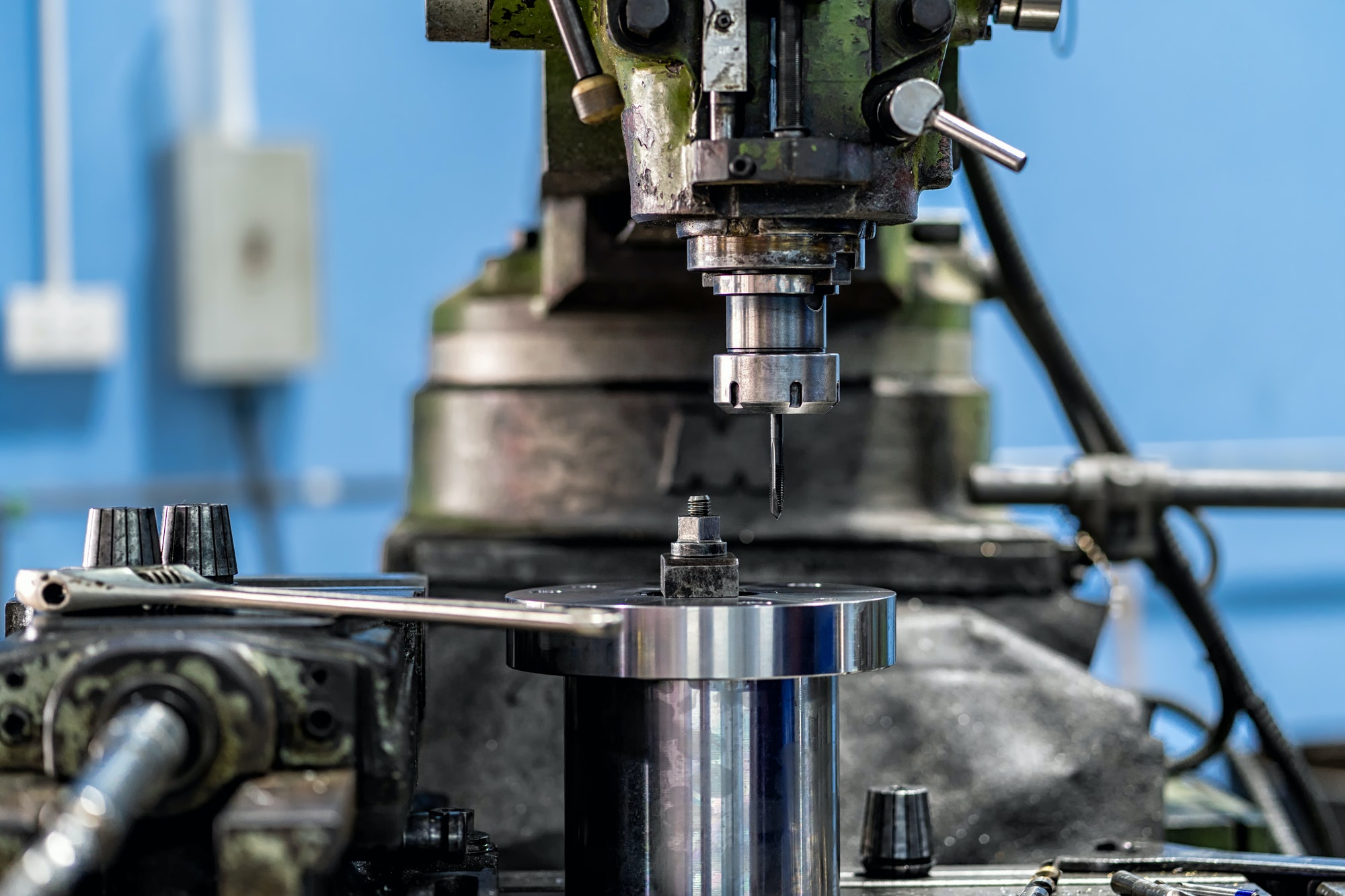

At M&A Grinding ApS, we specialize in providing high-quality stainless steel services specifically designed for the pharmaceutical industry. We understand the critical importance of maintaining sterile surfaces and ensuring that every piece of equipment meets the stringent requirements of Good Manufacturing Practices (GMP) and ISO regulations. Our comprehensive services include grinding, polishing, maintenance, and servicing of stainless steel tanks, containers, filter housings, mixing vessels, and more.

Whether you need routine maintenance, on-site repairs, or precise polishing, our team is ready to support your pharmaceutical operations with the highest level of hygiene and compliance. Explore how our services can help you maintain sterile environments and ensure the safe production of pharmaceutical products, while extending the lifespan of your stainless steel equipment.

You can contact us 24/7:

+45 91 863 566

+49 1523 8970 296

Maintaining sterile surfaces in pharmaceutical production is crucial to prevent contamination and ensure product safety. Raw or imperfect stainless steel surfaces can harbor bacteria and other contaminants, posing a serious risk in sterile environments. M&A Grinding ApS offers specialized grinding and polishing services for stainless steel equipment used in pharmaceutical production, ensuring that all surfaces are smooth, sterile, and compliant with strict GMP, FDA, and ISO standards.

Our grinding services are designed to remove surface imperfections, weld discolorations, and rough spots that could compromise the sterilization of the equipment. After grinding, we polish the surfaces to achieve a mirror-like finish, ensuring that your stainless steel equipment is easy to clean, sterilize, and maintain. Polished stainless steel not only meets the stringent hygiene requirements of the pharmaceutical industry but also improves the overall efficiency of cleaning and sterilization processes.

For example, stainless steel filter housings used in pharmaceutical filtration systems must maintain smooth, contamination-free surfaces to ensure the purity of the filtered products. Similarly, polished stainless steel tanks used in drug production must prevent bacterial growth and ensure sterility between batches. Our polishing services help pharmaceutical producers achieve the highest standards of purity and compliance, ensuring that their equipment remains safe and sterile.

Explore how our Grinding and Polishing of Stainless Steel services can enhance the sterility and performance of your pharmaceutical equipment.

In the pharmaceutical industry, equipment failure or contamination can have serious consequences, ranging from costly production downtime to compromised product safety. To ensure that your stainless steel equipment remains compliant with GMP, regular maintenance is essential. M&A Grinding ApS offers comprehensive maintenance services for stainless steel equipment used in pharmaceutical production, helping you maintain sterile, high-performance machines.

Our maintenance services include routine inspections, cleaning, polishing, and welding repairs, ensuring that your equipment remains in optimal condition throughout its lifecycle. By scheduling regular maintenance, you can identify and resolve potential issues before they lead to contamination or equipment failure. We ensure that all maintenance activities are carried out in compliance with GMP and ISO standards, reducing the risk of non-compliance and ensuring the safety of your pharmaceutical products.

For example, stainless steel tanks used in pharmaceutical production must be regularly inspected and maintained to ensure that their surfaces remain sterile, corrosion-free, and compliant with regulatory standards. Our maintenance services restore these tanks to their original condition by polishing surfaces, repairing welds, and addressing any signs of wear or contamination. Similarly, we maintain stainless steel filter housings, piping systems, and mixing tanks, ensuring that your entire pharmaceutical production system operates safely and efficiently.

Visit our Stainless Steel Maintenance page to learn more about how our maintenance services can help you maintain compliance and prevent contamination in your pharmaceutical operations.

Regular servicing of stainless steel equipment is crucial in the pharmaceutical industry to maintain sterility, efficiency, and regulatory compliance. Over time, even well-maintained equipment can become contaminated, corroded, or damaged, compromising the safety and performance of your processes. M&A Grinding ApS offers specialized servicing solutions for stainless steel equipment, helping pharmaceutical producers preserve the sterility and functionality of their equipment.

Our servicing solutions include deep cleaning, surface restoration, welding repairs, and polishing of equipment such as stainless steel tanks, containers, filter housings, and piping systems. By removing contaminants, corrosion, and surface defects, we ensure that your equipment remains sterile and compliant with GMP and FDA standards. Our services are designed to improve the efficiency and sterility of your pharmaceutical equipment, reduce the risk of contamination, and ensure product safety.

For example, stainless steel filter housings used in pharmaceutical filtration systems must be serviced regularly to ensure that their surfaces remain smooth and easy to clean. Our polishing and servicing process removes any contaminants or rough spots, ensuring that your filter housings maintain their sterility and performance. We also offer on-site servicing of stainless steel mixing vessels and tanks, allowing you to maintain your production schedules with minimal disruption.

Partnering with M&A Grinding ApS for your servicing solutions ensures that your pharmaceutical equipment remains sterile, compliant, and efficient. Learn more on our Stainless Steel Servicing page.

At M&A Grinding ApS, we understand that stainless steel is used across a wide range of industries, including Beverage Production, Food, Pharma, and Chemical Applications. We offer grinding and polishing, welding, and servicing solutions tailored to the unique requirements of each industry, ensuring that your products meet both hygiene, safety, and performance standards.

Below, you can read about the core principles that guide our work. We believe that no task is too small and that quality is a must.

Depending on the size of your project, we can start working on it within 12-72 hours. A large project may require more preparation time due to logistics.

We can perform the work at your location, but we can also pick up the parts from your factory and carry out the work in our own workshop.

In emergencies, we understand that a quick response is required. You can contact us at any of our numbers at any time, any day of the week.

All the work we perform follows strict quality assurance standards. However, should accidents occur (as they sometimes do), we have full insurance coverage for our work.

I farmaceutisk industri er det altafgørende at sikre, at rustfrit ståludstyr forbliver sterilt. Dårligt udførte svejsninger kan skabe sprækker, hvor bakterier og forurening kan ophobes, hvilket kompromitterer udstyrets sterilitet og fører til potentielle kontaminationsrisici. Hos M&A Grinding ApS tilbyder vi specialiserede svejsetjenester til rustfri ståludstyr af farmaceutisk kvalitet, hvilket sikrer, at dine tanke, beholdere og filterhuse opfylder de højeste standarder for renhed og ydeevne.

Vores dygtige svejsere bruger avancerede svejseteknikker til at skabe sømfrie, holdbare svejsninger, der eliminerer risikoen for forurening. Vi sikrer, at alle svejsninger er glatte, tætte og overholder GMP og ISO krav. Denne præcision er afgørende i sterile miljøer, hvor selv den mindste fejl kan kompromittere sikkerheden af dine farmaceutiske produkter. Uanset om du har brug for svejsning af nyt udstyr eller reparation af eksisterende systemer, leverer M&A Grinding ApS svejseløsninger, der opretholder sterilitet og strukturel integritet.

For eksempel skal rustfri stålblandingstanke, der anvendes i farmaceutisk produktion, forsegles perfekt for at forhindre lækager og sikre, at det sterile miljø bevares. Vores præcisionssvejsningstjenester hjælper farmaceutiske producenter med at sikre deres udstyrs sikkerhed og overholdelse, hvilket reducerer risikoen for produktkontaminering og udstyrsfejl.

Besøg vores Welding af Rustfrit Stål til Farmaceutisk Industri side for at lære mere om, hvordan vores svejsetjenester kan forbedre ydeevnen og sikkerheden af dit farmaceutiske udstyr.

Contact us today for more information!

(+45) 918 635 66

To provide the best experiences, we use technologies such as cookies to store and/or access device information. By consenting to these technologies, you allow us to process data such as browsing behavior or unique IDs on this site. If you do not consent or withdraw your consent, it may negatively impact certain features and functionality.