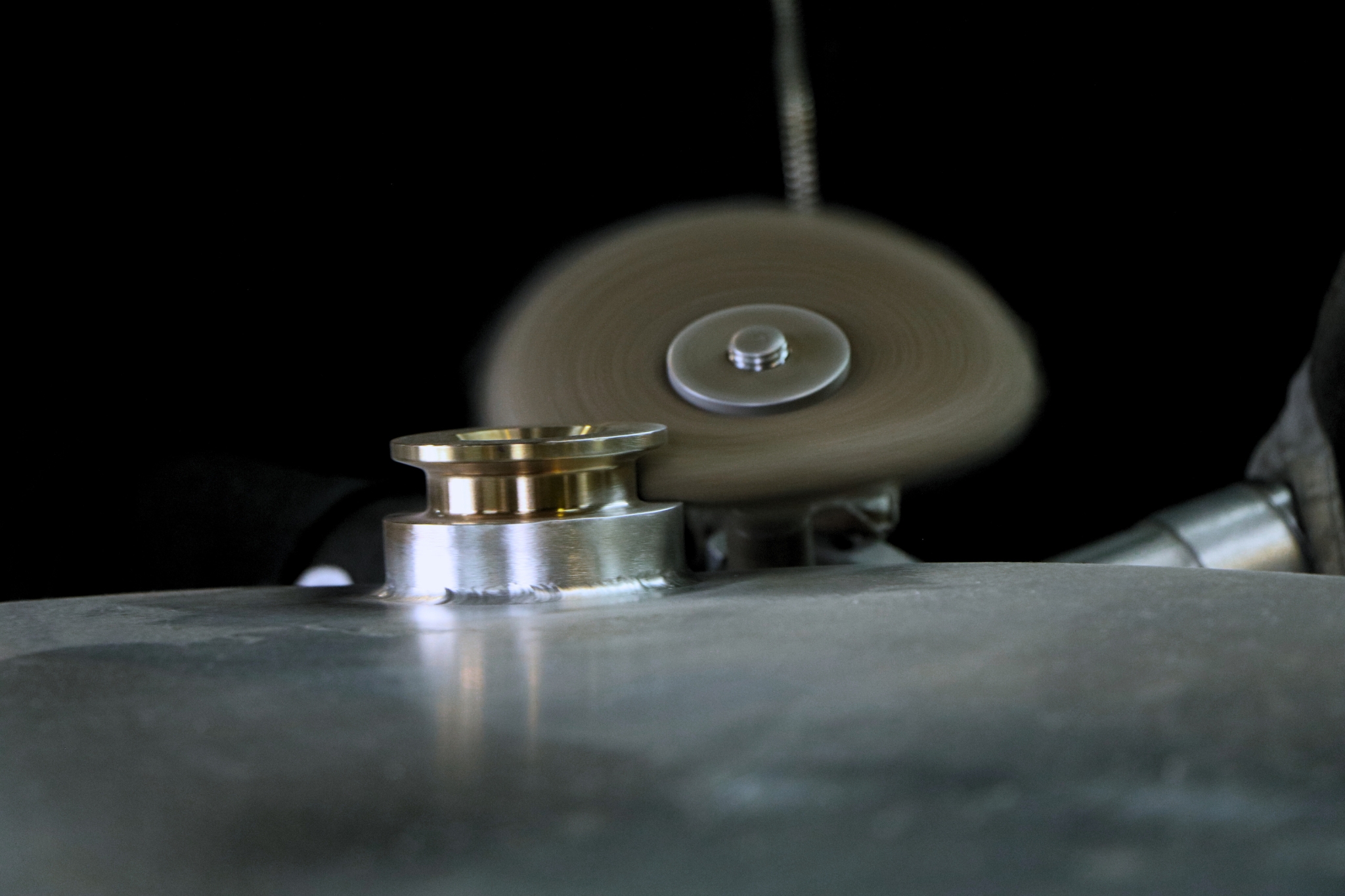

At M&A Grinding ApS, we specialize in delivering high-quality grinding and polishing of stainless steel for industrial applications across various industries, including dairy, food, pharmaceutical, chemical, fish industry, and many others. Stainless steel is widely used due to its durability, corrosion resistance, and hygienic properties, but the surface treatment of the material plays a crucial role in maintaining these benefits. Proper grinding and polishing ensure that stainless steel surfaces remain smooth, contamination-free, and corrosion-resistant, improving both performance and lifespan.

Our grinding and polishing services are designed to deliver optimal surfaces for stainless steel equipment, whether it is for tanks, silos, containers, filter housings, mixing tanks, coolers, or other stainless steel components. By offering precise grinding and polishing, we ensure that your equipment meets the strict hygiene and quality standards required in industries where cleanliness and safety are crucial.

We offer on-site services to minimize disruptions to your operations, as well as workshop-based services at our facility in Silkeborg for more complex projects. Our solutions comply with industry standards such as ISO, ensuring that your equipment remains compliant and performs optimally over time.

Explore our detailed grinding and polishing solutions for various stainless steel products, and contact us today to learn more about how we can support your operational needs.

You can contact us 24/7:

+45 91 863 566

+45 91 863 566

Stainless steel tanks are crucial components in industries such as dairy, food, pharmaceuticals, and chemical processing. These tanks are used for storing and processing liquids and powders, and the cleanliness and integrity of their surfaces are vital for ensuring product safety. At M&A Grinding ApS, we offer specialized grinding and polishing services for stainless steel tanks, ensuring that the surfaces are smooth, corrosion-resistant, and hygienic.

Grinding and polishing remove surface defects, weld discoloration, and contamination, resulting in a smooth, clean finish that meets the high standards required in industries where hygiene is critical. Our expert team uses advanced grinding techniques to eliminate rough surfaces that can harbor bacteria, making the tanks easier to clean and sterilize. We ensure that the polished surfaces comply with FDA, GMP, and HACCP regulations, making them ideal for use in food production, pharmaceutical manufacturing, and chemical storage.

For more details on how our grinding and polishing services can enhance the performance of your tanks, visit our Stainless Steel Tank Grinding and Polishing page.

Stainless steel silos are used for bulk storage of raw materials in industries such as food, dairy, and chemical processing. Maintaining the integrity of the stainless steel surface in these silos is crucial for preventing corrosion, contamination, and production downtime. M&A Grinding ApS offers professional grinding and polishing services for stainless steel silos, ensuring that the surfaces are smooth, strong, and resistant to environmental factors.

Polishing stainless steel silos helps remove surface defects such as weld discoloration and rough spots that can cause corrosion or bacterial growth. In industries where cleanliness is a priority, such as dairy and pharmaceuticals, our polishing process ensures that the silos meet food-grade standards and are easy to clean and maintain.

Visit our Stainless Steel Silo Grinding and Polishing page to learn more about our polishing services and how they can improve your storage solutions.

Rustfri ståls containere er essentielle til opbevaring, transport og blanding af materialer i industrier som fødevareproduktion, farmaceutisk, kemisk og mejeriproduktion. Overfladefinishens integritet på disse containere påvirker direkte deres korrosionsbestandighed, hygiejne og levetid. M&A Grinding ApS tilbyder ekspertslibning og polering til rustfri ståls containere, hvilket sikrer, at dine containere bevarer deres styrke, renhed og overholder industristandarder.

Vores poleringstjenester fokuserer på at fjerne overfladefejl, der kan fange bakterier eller føre til korrosion, hvilket efterlader en glat, hygiejnisk finish, der opfylder de strenge krav fra industrier som fødevareforarbejdning og farmaceutisk fremstilling. Vi sikrer, at vores polerede finish opfylder FDA, GMP og HACCP standarder, hvilket beskytter dine produkter mod kontaminering og sikrer langvarig holdbarhed.

Udforsk vores Rustfri Ståls Containere Slibning og Polering side for at se, hvordan vores tjenester kan forbedre funktionaliteten og levetiden af dine containere.

Stainless steel filter housings are an integral part of filtration systems in industries such as pharmaceuticals, food production, the fish industry, and chemical manufacturing. These housings must maintain a smooth, clean, and sterile surface to ensure that the filtration systems operate effectively without contamination. M&A Grinding ApS provides specialized grinding and polishing services for stainless steel filter housings, ensuring that each surface is smooth, defect-free, and easy to sterilize.

Our grinding and polishing services ensure that the filter housings are corrosion-resistant, tight, and free from contaminants, extending the lifespan of your filtration systems and enhancing their overall performance. By polishing stainless steel to a high standard, we ensure that the filter housings comply with FDA, GMP, and ISO regulations, making them suitable for use in sterile environments.

Visit our Stainless Steel Filter Housing Grinding and Polishing page to learn more about our services and how they can enhance the performance of your filtration systems.

Stainless steel coolers play a critical role in maintaining temperature control in industries such as dairy, food, pharmaceuticals, and chemical processing. The quality of the surface treatment on these coolers directly impacts their corrosion resistance and ease of cleaning. M&A Grinding ApS offers professional grinding and polishing services for stainless steel coolers, ensuring that the equipment remains in optimal condition for temperature control.

By polishing stainless steel surfaces, we remove any defects that could compromise the coolers' performance or cleanliness.

Our polished surfaces meet the hygiene standards required in industries where cleanliness is critical, such as food production and pharmaceuticals, ensuring that the coolers are easy to clean and maintain. Our polishing services help extend the lifespan of the coolers while maintaining compliance with FDA, GMP, and ISO standards.

For more information on our grinding and polishing services for stainless steel coolers, visit our Stainless Steel Coolers Grinding and Polishing page.

Stainless steel mixing tanks are crucial for the mixing and processing of materials in industries such as food, dairy, pharmaceuticals, and chemical processing. The cleanliness and surface treatment of these tanks play a key role in ensuring product quality and safety. M&A Grinding ApS offers expert grinding and polishing services for stainless steel mixing tanks, ensuring that the tanks meet the highest standards for cleanliness, durability, and regulatory compliance.

Our polishing process focuses on removing surface defects such as weld discoloration or rough spots that can harbor bacteria or contaminants. By achieving a smooth, hygienic surface, we ensure that the mixing tanks are easy to clean and maintain, and comply with industry regulations such as HACCP, FDA, and GMP. Whether you need polishing for new tanks or wish to restore existing ones, our grinding and polishing services ensure your equipment delivers optimal performance.

To learn more about our mixing tank polishing services, visit our Stainless Steel Mixing Tanks Grinding and Polishing page.

At M&A Grinding ApS, we have a proven track record of delivering expert grinding and polishing services for stainless steel equipment across various industries. From dairy and food production to pharmaceuticals and chemical processing, our services are tailored to meet the specific regulatory and operational requirements of each industry. We understand the importance of maintaining hygienic, corrosion-resistant surfaces, and we work to ensure that your stainless steel equipment remains compliant with the highest standards within FDA, GMP, HACCP, and ISO.

In the food and dairy industries, where cleanliness is critical, we prioritize achieving smooth, contamination-free surfaces that are easy to clean and sterilize. For our pharmaceutical customers, we focus on maintaining sterile surfaces in tanks, filter housings, and mixing vessels, ensuring that they meet the stringent requirements of GMP and FDA regulations. In chemical processing, we ensure that the equipment can withstand corrosive materials by improving the corrosion resistance of stainless steel surfaces.

Stainless steel filter housings are an integral part of filtration systems in industries such as pharmaceuticals, food production, the fish industry, and chemical manufacturing. These housings must maintain a smooth, clean, and sterile surface to ensure that the filtration systems operate effectively without contamination. M&A Grinding ApS provides specialized grinding and polishing services for stainless steel filter housings, ensuring that each surface is smooth, defect-free, and easy to sterilize.

Our grinding and polishing services ensure that the filter housings are corrosion-resistant, tight, and free from contaminants, extending the lifespan of your filtration systems and enhancing their overall performance. By polishing stainless steel to a high standard, we ensure that the filter housings comply with FDA, GMP, and ISO regulations, making them suitable for use in sterile environments.

Visit our Stainless Steel Filter Housing Grinding and Polishing page to learn more about our services and how they can enhance the performance of your filtration systems.

Below, you can read about the core principles that guide our work. We believe that no task is too small and that quality is a must.

Depending on the size of your project, we can start working on it within 12-72 hours. A large project may require more preparation time due to logistics.

We can perform the work at your location, but we can also pick up the parts from your factory and carry out the work in our own workshop.

In emergencies, we understand that a quick response is required. You can contact us at any of our numbers at any time, any day of the week.

All the work we perform follows strict quality assurance standards. However, should accidents occur (as they sometimes do), we have full insurance coverage for our work.

Contact us today for more information!

(+45) 918 635 66

To provide the best experiences, we use technologies such as cookies to store and/or access device information. By consenting to these technologies, you allow us to process data such as browsing behavior or unique IDs on this site. If you do not consent or withdraw your consent, it may negatively impact certain features and functionality.